As an authorised distributor, we are committed to working in the best interests of our customers in the area of maintenance and repair:

- Sales advice

- Well-trained, competent and knowledgeable staff

- The best understanding and relevant experience of the process requirements in each discipline

- Advice on minimising overall costs, optimising lead times and improving processes

- Always up-to-date industry knowledge

- Building long-term business relationships

Products and solutions from NSK

NSK bearings effectively cope with challenging operating environments and reduce operating costs.

The focus is on quality, development and new product design.

- NSK ball bearing

- NSK precision bearing

- Rolling bearing NSK

- Spherical roller, cylindrical roller, tapered roller bearings NSK

- Thrust, needle roller bearings NSK

- Bearing units NSK

- Linear guides, ball screws

- NSK spindle bearings

- Customer solutions

NSK products and solutions can be found wherever something moves – even in the harshest environments and conditions.

NSK precision roller bearings are used in wind turbines and machine tools, and NSK linear technology can be found in production lines.

At NSK’s more than 200 service centres and production sites around the world, approximately 24,000 employees work closely with customers to maximise NSK’s international potential and strength.

Materials for download

Spindle bearings

The ROBUSTSHOT range of high-precision bearings for angular contact spindles is designed to meet the demanding requirements of spindles with integrated electric motors.

It ensures quiet and reliable spindle operation, rapid acceleration and deceleration, higher speeds (over 3 million dmn) and longer life.

The innovative ROBUSTSHOT range of spindle bearings meets the constant demand from global machine tool manufacturers to increase spindle speeds to enable as many operations as possible to be carried out within a single machine.

High-speed operation with the shortest possible spindle start-up and run times are necessary conditions to achieve this.

Reliable and continuous lubrication of the raceways is therefore a particular challenge for bearing manufacturers; without a suitable lubrication system, bearing operation under such demanding conditions is completely impossible.

The ROBUSTSHOT range is available from 30 mm to 110 mm bore diameter and is available in a wide range of configurations: the SU universally matched bearing, the DU universally assembled bearing pair, the DB bearing pair (back to back), the DF bearing pair (face to face), the DT bearing pair (tandem), as well as triple and quadruple bearings.

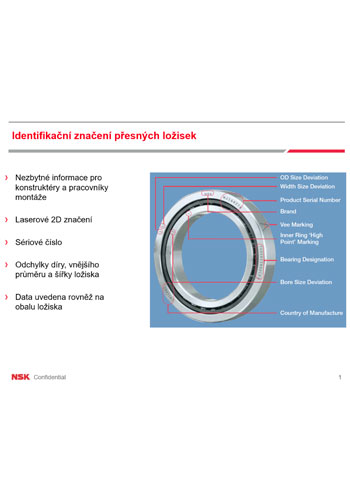

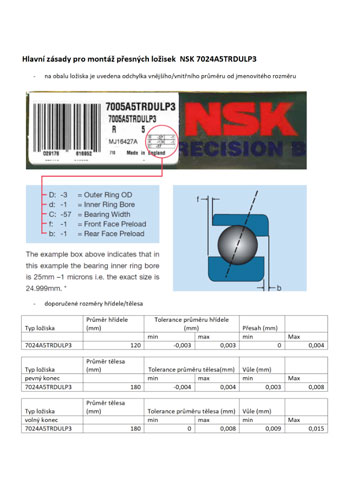

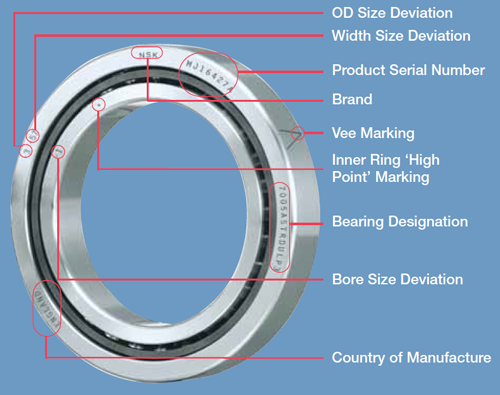

Identification marking of precision bearings

- Essential information for designers and assembly workers

- 2D laser marking

- Serial number

- Deviations in bore, outer diameter and bearing width

- Data also shown on the bearing packaging

NSK linear line

TWICE THE OPERATING LIFE OF LINEAR NH/NS LINES

NSK NH/NS series linear lines have twice the service life of LH/LS series linear lines.

The new design ensures a much more even distribution of forces between the balls and the orbit.

As a result, the new lines have significantly lower stresses in the contact area at the same load, resulting in higher dynamic load capacity values when calculated according to the relevant ISO standards.

The result: the basic dynamic load capacity is 30% higher and the service life, given by the resistance to fatigue damage of the line, more than doubled.

For example, the nominal service life of the NH25AN linear line is 2.24 times that of the LH25AN line.

At the same time, the noise level is 3 dB(A) lower.

In addition, the X-shaped arrangement of the balls preserved thehigh “tilting” capability of the carriage with respect to the rail.

This results in a relatively low internal load compared to the O arrangement. The new linear guides therefore have wider mounting tolerances without significantly affecting their service life.

The new lines can be used with the proven NSK K1 lubrication units. The advantage is that compatibility is maintained: both the older and the new lines can be used on the same machine or plant at the same time.

In this case, however, it is necessary to take into account the lower dynamic load capacity of the older series lines, since the lifetime of the entire plant is determined by the lifetime of the weakest link in the mechanical structure.

Another key advantage of the new generation of linear guides is the ability to operate at much higher speeds without any structural modifications.

Because they are equipped with a high-speed reciprocating system, they have up to three times the maximum permissible speed of their predecessors: instead of 100 m/min, NH/NS linear guides have a maximum speed of 150 to 300 m/min.

The movement is much smoother and quieter thanks to the completely redesigned ball orbit design.

The balls now move from the contact zone with the rail to the return cover much more quietly than before.

The new NH/NS linear guides are suitable for precision movements with small clearances in machine tools, medical technology, semiconductor manufacturing, packaging machines, robots and manipulators.

The new linear guides can withstand much higher loads than their previous series.

Older lines can therefore be replaced by significantly smaller lines of the new generation while maintaining the same operating life.

For example, instead of the older LH30AN line, a designer can now use the NH25AN line with a cross-section 20% narrower and 10% smaller.

The weight is 30% less.

EN_Precision_Machine.pdf

Customer support

Are you interested in more information and specifications of our products? Interested in current prices? Need to contact service, technical or support? Our experts are at your service!

Availability

We offer a wide range of products ready for immediate dispatch from our own warehouse.

Professional support

Our team of experts is here to provide you with technical support, advice and information about our products.

Certification

Our employees are regularly trained directly by suppliers to ensure they have up-to-date knowledge of standards and technologies.

Fair prices

Our pricing policy is transparent and fair. We offer fair prices, which is especially appreciated by our long-term customers.

Keep in touch with us

For any questions or inquiries, please do not hesitate to contact us!

Company headquarters / Central warehouse

Nad Sládečkem 600

390 02 Tábor

Establishments

Infoline

+420 777 284 100

+420 381 258 658